Threaded forged fittings

Forged Threaded Fittings

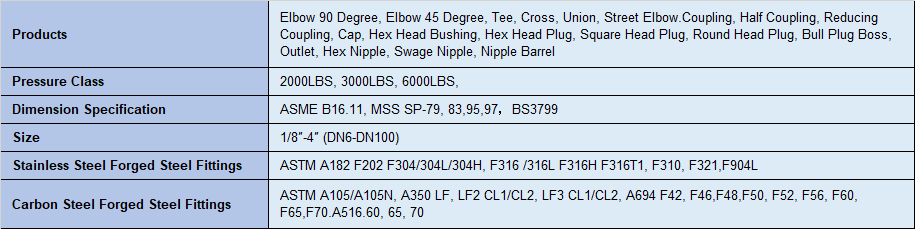

Cangzhou Taichang Pipeline Equipment Co., Ltd is one of the prominent manufacturer, exporter and supplier of forged threaded fittings manufactured in accordance to ASME B16.11.Forged threaded fittings are available ex-stock in all major stainless steel grades (ASTM A182 F316L, F304L), carbon steel and alloy steel grades. We offer varous types of threaded fittings including threaded elbow, threaded tees, threaded cross, threaded union, nipple barrel and more. Threaded fittings are widely used in piping systems across major industries such as petrochemicals, power generation, ship building, diary industry, breweries, waste water treatment chemical, pharmaceuticals and others.

Forged Threaded 90 Degree Elbow

Forged Threaded 45 Degree Elbow

Forged Threaded Tee

Forged Threaded Cross

Nipple Barrel

Half Nipple

Threaded Coupling

Half Coupling

Forged Threaded Union

Forged Threaded Outlet

Threadolet

Forged Threaded Cap

Square Head Plug

Hex Head Plug

High Pressure Socket Weld Forged Fittings

Advantages of Threaded Connections:

The primary benefits of threaded fittings are

- Threaded Connections are rapid to install.

- Their leakage integrity is reliable for applications requiring low temperature and they are highly suitable for low-pressure applications as well.

- Installation is time-saving and doesn’t require any special skills.

- The connecting process requires less force.

- Their parts are detachable.

- They are affordable and cheaper. Hence, they can be considered to be cost-effective.

Disadvantages of Threaded Connections:

Along with advantages, they offer some disadvantages as well, they are:

- They are not suitable for high-temperature-pressure applications.

- Threads might not handle a corrosive environment well as there possess chances of corrosion.

- Due to temperature changes, there may be a possibility of leakage problems.

- Fatigue damage can occur for cyclic services.

- Their strength is less compared to that of welding.

- Due to the high stress amplification effects induced by the sharp notches at the base of the threads, vibration can cause fatigue failures of screwed pipe joints.

Further Suggestions:

In corrosive and erosive situations or where cyclic loads may take place, threaded joints should be avoided.

Threaded joint pipework should be laid correctly to minimize joint stress, paying particular attention to strains from thermal expansion and valve operation.

Under extremely cyclic situations, threaded components of a specialized character that are not subject to external moment loading, like thermometer wells, may be employed.

Difference between malleable iron and forged threaded fittings:

Plumbing and light industrial applications both use fittings made of malleable iron. These threaded fittings are composed of forged steel and have a high-pressure rating. One significant distinction is that you cannot weld a threaded fitting while you may with a fitting made of malleable iron. Again, this is a threaded fitting, but depending on your use, you could be better off using forged carbon steel if you need to weld it. Additionally, fittings made of malleable iron have 150- and 300-pound strength ratings. Much less pressure can be applied to a threaded fitting, which has a 3000 and 6000-pound pressure rating.

Difference between Threaded fittings and socket welded fittings:

When it comes to threaded fittings, screws are used to attach threaded fittings to pipes or pipe parts. They leak more easily and have less strength and dependability. They can be obtained in 2000#, 3000#, and 6000# pressure classes.

On the other hand, Socket welded fittings are linked by fillet weldings. They are more trustworthy and give better results. They are stronger and more enduringly connected. Available in additional pressure class 9000#.

Conclusion:

Pressure fitting is a wide range of fittings which includes threaded pipe fitting. The pressure ratings for threaded fittings range from 2000 pounds to 6000 pounds. 2000 pounds basically corresponds to schedule 80, whereas 3000 pounds roughly corresponds to schedule 160. The maximum pressure rating for the 3000-pound threaded fitting is 3000 pounds. The pressure rating is a function of temperature, therefore as the temperature rises, the pressure rating decreases, making this a bit more difficult. They come in forged carbon steel, A105, A105 N, stainless steel, and nickel alloys, among other materials.

They prove to be popularly used in the piping industry as they offer various advantages despite some drawbacks. They have high demand when the applications require delicacy in terms of the temperature along with the pressure put on them.

Marking & Packing

Products are packaged to ensure that there is no damage during transit. In case of exports, standard export packaging is done in wooden cases. All elbow fitings are marked with Grade, heat No. , Size, Degree and our trade mark. On special requests we can also make custom marking on our products.

Quality Assurance

In Taichang all fittings and flanges are subiect to strict inspection at each stage of the production process from starting material purchasing to product dispatch. They are visually examined for conformity to ASTM ASME MSS DIN EN and JIS codes and standards. Upon request, official certified inspection Agencies can be called in to witness the material reports dimensions and quality conformity of products.

Test reports

Manufacturer Test Certificate as per EN 10204 / 3.1B, Raw Materials Certificate, 100% Radiography Test Report, Third

Party Inspection Report.