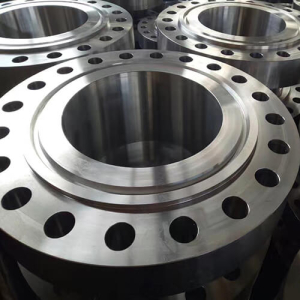

Carbon Steel Weld neck Flanges (WNRF/WNFF/WNRTJ)

Carbon Steel Weld neck Flanges (WNRF/WNFF/WNRTJ)

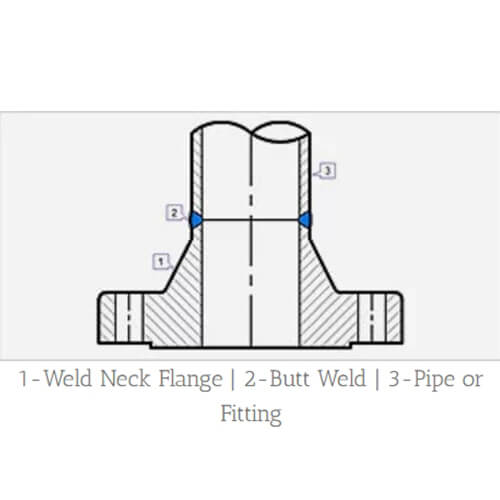

Weld neck flange is a kind of integral flange, refers to the flange with a neck and has a round pipe transition and butt-welding connection with the pipe.

Weld neck(WN) flange is not easy to deformation, good sealing, wide range of applications, there are corresponding rigidity and elasticity requirements and reasonable butt-welding thinning transition, welding mouth from the joint surface distance, the joint surface from the welding temperature deformation, it takes a more complex Loudspeaker-shaped body structure, for pressure or temperature fluctuations in large quantities of the pipeline or high temperature, high pressure and low-temperature pipelines, generally used for the connection of the pipeline and valves with a PN greater than 2.5MPa; Also used to transport expensive, flammable, explosive media on the pipeline.

Product Details

Size: 1/2″ (15 NB) to 100″ (2500NB)

Standard: ANSI ASME BS DIN EN JIS

Pressure: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc.

Type: Threaded flange, weld neck flange, blind flange, slip on flange, lap joint flange, socket weld flange.

Applications: Chemical industry, construction, water supply, drainage, petroleum, light and heavy industry, refrigeration, sanitation, plumbing, fire protection, electric power, aerospace, shipbuilding, etc.

Other Descriptions

Weld neck flanges are generally made by forging or forging and rolling process. When steel plate or steel section is used for manufacturing, the following requirements shall be met: 1. Butt-welding flanges shall be ultrasonically detected and free from delamination defects; 2. They shall be cut into strips along the rolling direction of the steel and butt-welded into rings by bending, and the surface of the steel shall be formed into the column surface of the rings. No steel plate shall be directly machined into necked butt-welded flanges; 3. The butt-welds of the rings shall be full penetration welds; 4. The butt-welds of the rings shall be subjected to post-welding heat treatment and 100% ray or ultrasonic flaw detection.

The slope of the outside of the neck of the weld neck flange should be no more than 70°. Weld neck flange in the production and welding of strict control of technical parameters, to ensure that can be in the production and use to give full play to the role and value.