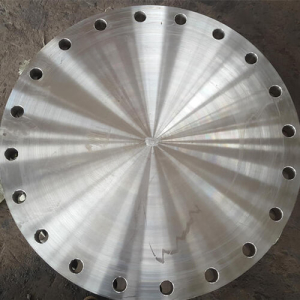

Carbon steel blind flange (BLRF BLFF BLRTJ)

Carbon steel blind flange (BLRF BLFF BLRTJ)

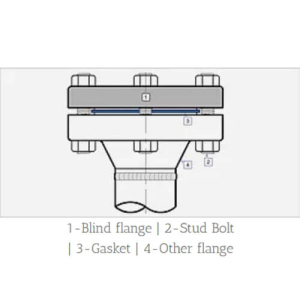

Blind flange, also known as flange blind or blind flange cover, is a special flange connector characterized by the absence of a hole in the middle. Its main functions include sealing the end of the pipe and facilitating the removal of debris from the pipe during maintenance. The structure of a blind flange usually consists of a blind flange disk and a flange gasket, while the sealing member can be metal (such as carbon steel, alloy steel, stainless steel) or plastic. Unlike ordinary flanges, blind flanges do not require additional fittings for connection and can be directly installed in the closed part of the piping system. Due to its better closure performance, blind flanges are widely used in piping systems in petrochemical, pharmaceutical, food and other industries.

Product Details

- Size: 1/2″ (15 NB) to 100″ (2500NB)

- Standard: ANSI ASME BS DIN EN JIS

- Pressure: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc.

- Type: Threaded flange, weld neck flange, blind flange, slip on flange, lap joint flange, socket weld flange.

- Applications: Chemical industry, construction, water supply, drainage, petroleum, light and heavy industry, refrigeration, sanitation, plumbing, fire protection, electric power, aerospace, shipbuilding, etc.

Other Descriptions

Blind flange is a commonly used pipeline closure fitting, which is usually used in occasions that need to be closed but need to be unclosed from time to time. It is usually installed in the flange gap of a pipeline and bolted tightly to improve the sealing performance of the pipeline. The seals of the blind are usually made of rubber, plastic and other elastic materials, so as to facilitate the removal and replacement. The purpose of a blind is to close off a portion of the piping system to facilitate maintenance and access to the piping.

There are differences between blind flanges and blind plates in terms of usage scenarios, structure and sealing performance. Blind flanges are mainly used in the “dead end” of piping systems, while blind plates are commonly used for maintenance, cleaning, inspection or replacement of piping equipment and other scenarios. The sealing principle of blind flanges is through the combination of blocking parts and pipe flange threads, through the fastening nut to realize the sealing, while the blind plate mainly relies on the sealing effect of the gasket to prevent media leakage.

When using blind flanges and blind plates, they should be installed and used in strict accordance with relevant requirements to ensure that their sealing performance and safety performance meet the requirements. Parameters such as size specification and working pressure must be matched with the requirements of piping system, otherwise it may lead to leakage or other dangerous accidents. During long-term use, regular inspection and maintenance should be carried out to replace damaged sealing materials and parts in time to ensure its normal operation and service life.