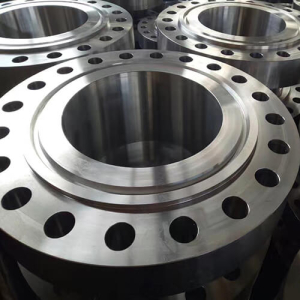

Carbon Steel Socket Weld flange (SWRF, SWFF, SWRTJ)

Carbon Steel Socket Weld flange (SWRF, SWFF, SWRTJ)

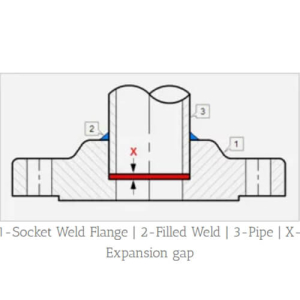

Socket welding flanges are flanges where the end of the pipe is inserted into the flange ring step and welded at the end and outside of the pipe. There are two kinds of flanges with and without neck. Necked pipe flanges have good rigidity, small welding deformation, better sealing, and can be used for pressures of 1.0~10.0MPa

Product Details

Size: 1/2″ (15 NB) to 100″ (2500NB)

Standard: ANSI ASME BS DIN EN JIS

Pressure: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc.

Type: Threaded flange, weld neck flange, blind flange, slip on flange, lap joint flange, socket weld flange.

Applications: Chemical industry, construction, water supply, drainage, petroleum, light and heavy industry, refrigeration, sanitation, plumbing, fire protection, electric power, aerospace, shipbuilding, etc.

Other Descriptions

Advantages and disadvantages of socket weld flanges :

Socket welding is usually used for small pipes with diameters less than DN40 and is more economical.

Socket welding can be used for magnetic particles or permeability testing (carbon powder, penetrating carbon steel) such as stainless steel), if the fluid in the pipeline does not require high welding, it is recommended to use socket welding, easy to test the type of connection is mainly for small diameter valves and pipes for pipe joints and pipe welding, small diameter pipes are usually thin-walled, prone to edge misalignment and ablation, and difficult to butt weld, suitable for socket welding and Socket.

Welded socket is often used under high pressure due to its reinforcing effect, but socket welding has its drawbacks, one of which is that the stress condition after welding is not good and it is difficult to melt completely. The trend is: piping systems with gaps, so not suitable for crevice corrosion-sensitive media and cleanliness requirements of the piping system; the use of socket welding; and ultra-high-pressure pipelines. Wall thicknesses are large even in small-diameter pipelines, and socket welding can be avoided as much as possible by butt welding.