F3 Series

Multistage blowers and compressors

In contrast to single-stage radial blowers and compressors, multistage variants from FIMA each have multiple impellers mounted on a rotor. This allows extremely high pressures to be generated in a relatively small space.

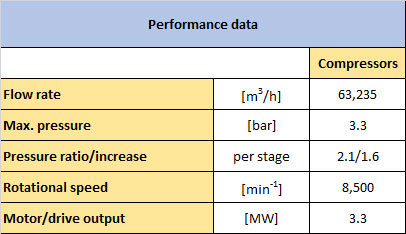

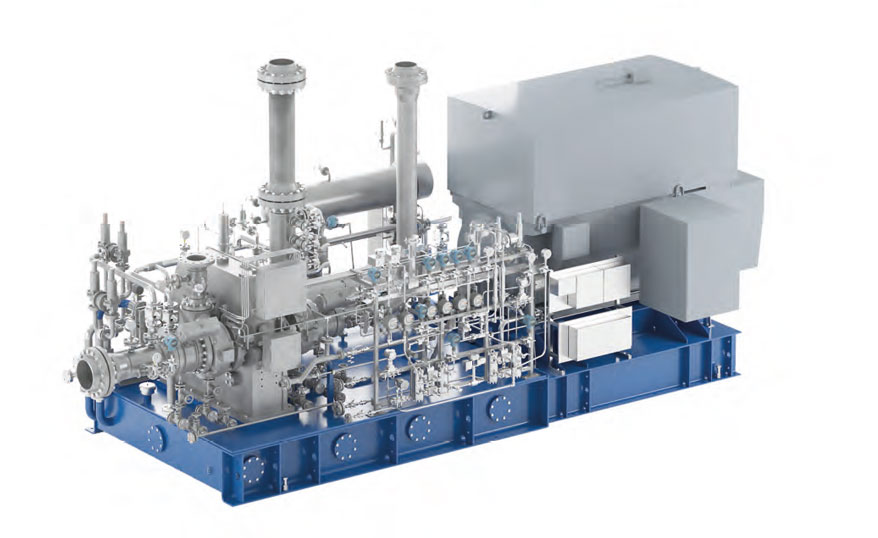

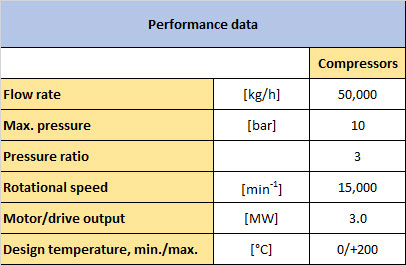

PP cascade (2-stage)

If several process steps are connec- ted in series and the starting product from each step is further processed in the next step, then this is referred to as a cascade. This method is also used in the production of polypropylene.

In plants using the PP cascade process, recycle gas compressors from FIMA are also installed. If higher pressure increases are required, two-stage compressors are used. FIMA uses a single pinion compressor design in which the axial forces of the two stages balance each other out. This guarantees optimal efficiency and an optimum machine service life. For applications that require intermediate cooling, FIMA supplies complete solutions that include special cooling systems.

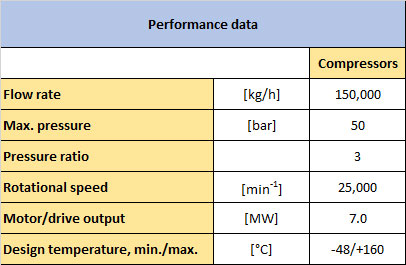

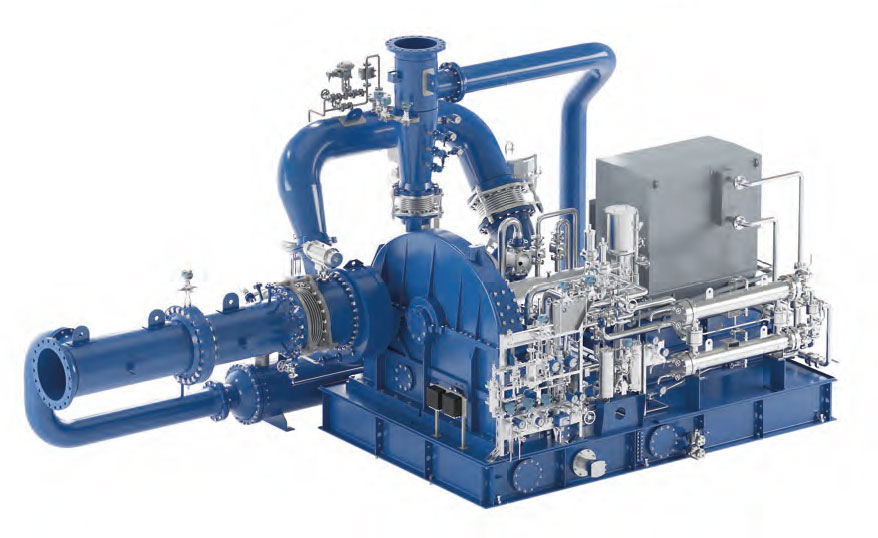

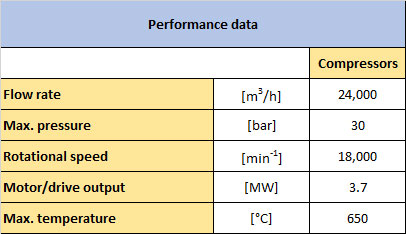

Methanol/ Ethanol (2-stage)

Methanol is produced using syngas or CO and H2 in a large-scale process. In terms of range of applications and production volume, metha-nol is the most important alcohol. It serves as a precursor product for organic syntheses, e.g., of plastics. Besides being produced through the fermentation of biomass, ethanol can also be synthetically produced. In this case, it is frequently processed further into solvents, antifreeze or fuel.

The sample performance data originate from a methanol plant in Brazil in which a FIMA two-stage integrally geared compressor is used to compress and transport the methanol vapor in a secondary process.

Hot gas compressors (2-stage)

Two-stage compressors with precisely specified performance data at high pressure and temperature are a unique offering from FIMA, otherwise very hard to find on the market. In one example, thanks to its decades-long experience in the process gas industry and in manufacturing of machines for various application areas, FIMA was the only company able to design and build the compressor.

The compressor recycles combustion exhaust gas in a gas turbine test rig. The customer thus is able to test its gas turbines under full load. At the same time, operating costs are lowered because the exhaust gas no longer has to be mixed artificially. With our technical know-how and resourceful employees, FIMA is ready to take on challenges and find customer-oriented solutions that go beyond the possibilities of the competition.

Air compressors (2-stage)

One use for two-stage FIMA air compressors is for fermentation air. The fermentation air compressors are used in such applications as the production of citric acid. The air can be drawn in via intake filters, compressed in two compressor stages, and then fed to the process.

These types of compressors are used, for example, for aeration or supply of atmospherically operated plants. In these biotechnological applications, the static and dynamic pressure losses must be overcome.

Two-stage air compressors are also used for vapor recompression in methanol applications.