FORCE BALL VALVES

Floating Ball Valves

Standard design features, product line range, material selection, and a centrally-located operations facility all combine to make FORCE the first choice for floating ball valves. The inherent ball valve characteristics of quick quarter-turn operation, bi-directional shut-off capability, ease of automation, and low maintenance are enhanced with many additional features such as stainless steel gland, grafoil stem packing, heavy bolting meeting NACE MR0175.

The pressure equalization hole at the top of the ball combined with seat design are engineered to maintain the pressure balance in the line and in the body cavity while the valve is in the open or closed position.

API 6D or API 598 to assure the integrity of the shell and seals, and final inspection to confirm that all marking, tagging and processing have been performed in accordance with FORCE and industry standards.

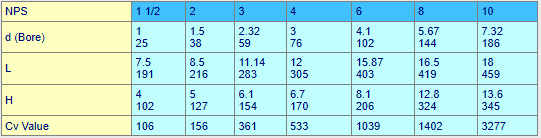

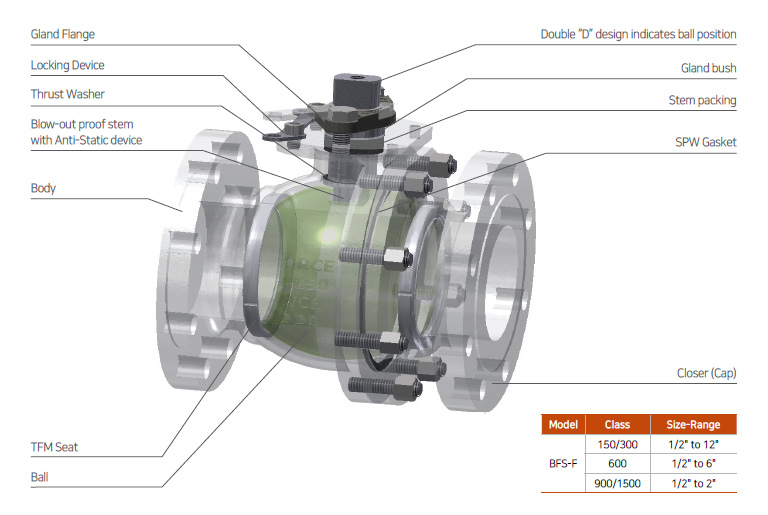

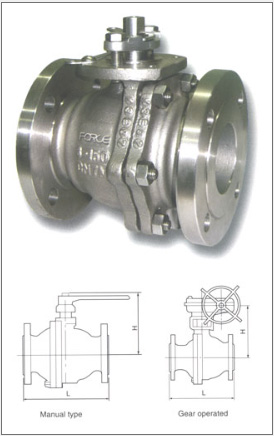

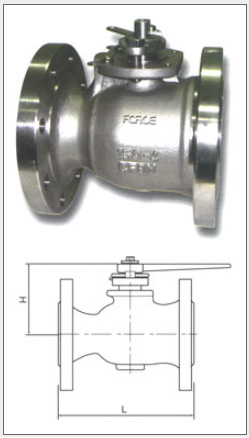

* This is an illustrated of a typical BUS reduced port, Uni-body(One-piece), floating type ball valve exhibiting the basic design concept.

* The actual design of a valve may be slightly different from this illustration, depending on its size and pressure class.

* This is an illustrated of a typical reduced port, Split-body(Two-piece), floating type ball valve exhibiting the basic design concept.

* The actual design of a valve may be slightly different from this illustration, depending on its size and pressure class.

BODY JOINT CONSTRUCTION

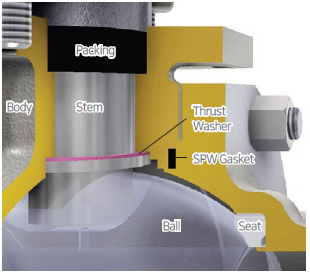

The One-piece/ Uni-body Side entry design, Graphite ring or O’ring, Viton(upon request) seals ensure absolute seal integrity. The Two-piece/ Split-body Side entry designs include a tight toleranced overlapping metal fit between the body and the adapter to minimize any possibility of movement due to pipeline stress. A special high temperature Spiral wound stainless steel/ grafoil filled gasket is utilized for absolute seal. This gasket is encapsulated by the body and adapted on all four sides. Body and adaptors are dimensioned for metal contact to ensure correct gasket crush.

SEAT DESIGN

Standard valves utilise reinforced PTFE seats for maximum chemical compatibility and are designed to FLEX ensuring positive sealing performance across a wide pressure range whilst providing controlled operational torque and cavity relief capability. Reliable sealing is enhanced via precise pre-compression of the ball between the two flexing seat rings allowing the ball to float along the valve axis providing bubble tight and bi-di rectional performance.

BLOW-OUT PROOF STEM

Stem is made separately from the ball, anti blow-up design with suitable PTFE and graphite rings and antistatic device. The lower end of the stem is designed with an integral collar to be blow-out proof. It also functions as the backseat for assured stem sealing.

ANTI-STATIC DEVICE

All floating flanged ball valves include dual grounding system from stem to ball and stem to body. Valve testing to API 6D 24edition-Annex.H or ISO 17292 was performed for all sizes, and witnessed by a third party inspection company. An anti-static feature is provided to ensure electrical continuity for assured stem sealing.

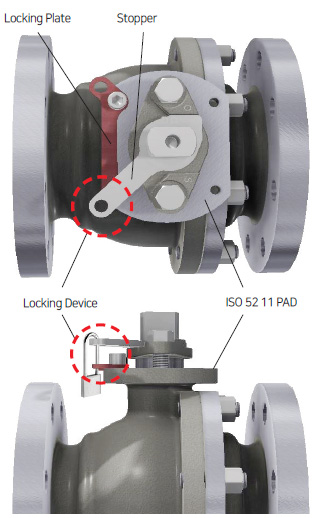

ISO 5211 & EN ACTUATOR MOUNTING

Allows precise mounting of actuator, mounting bolts are independent from stem packing gland bolts or cover bolts. Exact alignment reduces torque requirements and prevents side load causing out-ofline wear and additional stress to stem.

TOP WORKS/ LOCKING DEVICE

Stem head design provides mounting of the lever handle always in parallel to the flow passage. Facility for mounting a locking device for prevention of accidental valve operation is provided

▶ BU & BF Series Floating Ball Valves

- BF Series – Full Bore 1/2″ to 12″ ANSI 150/300

- BF Series – Full Bore 1/2″ to 6″ & Reduced Bore 3″ to 6″ – ANSI 600

- BF Series – Full Bore 1/2″ to 1-1/2″ & Reduced Bore 3″ to 6″ – ANSI 900/1500

- BU Series – Reduced Bore 1-1/2″ to 12″ – ANSI 150/300

- BF ANSI 150/300

- BF ANSI 600

- BF ANSI 900/1500

- BU ANSI 150/300

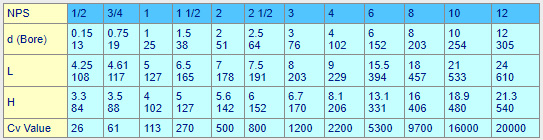

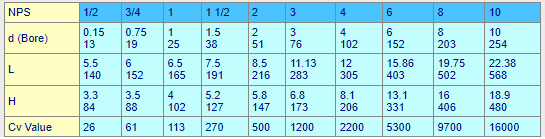

BF Series Floating Ball Valves ANSI 150 & 300

- Full bore : size 1/2″ to 12″

- For pipeline, oilfield or process industry

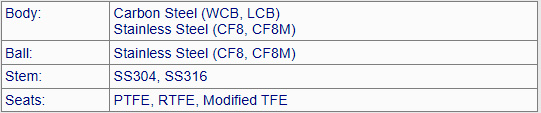

Standard Materials

Class 150 Dimensions(Units: inch / mm)

Class 300 Dimensions(Units: inch / mm) |

|

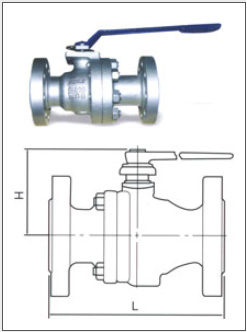

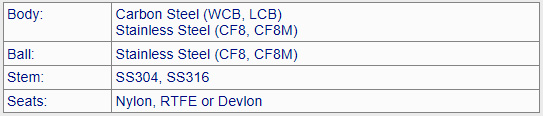

BF Series Floating Ball Valves ANSI 600

- Full bore: size 1/2″ to 6″

- Reduced bore: Sizes 3″ to 6″

- For oilfield or process industry

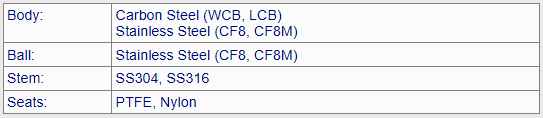

Standard Materials

Class 600 Dimensions(Units: inch / mm) |

|

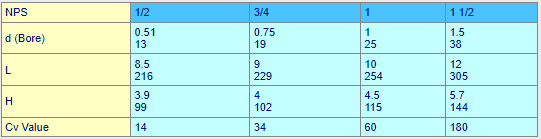

BF Series Floating Ball Valves ANSI 900/1500

- Full bore: size 1/2″ to 1-1/2″

- Reduced bore: Sizes 3″ to 6″

- For oilfield or process industry

Standard Materials

Class 900 & 1500 Dimensions(Units: inch / mm) |

|

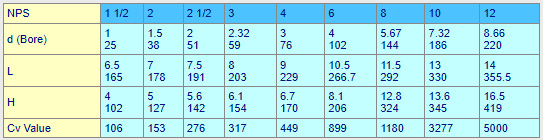

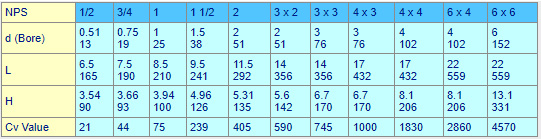

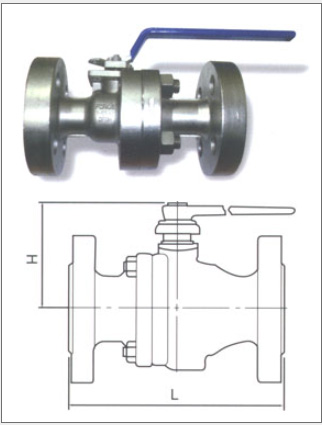

BU Series Floating Ball Valves ANSI 150/300

- Reduced bore: size 1-1/2″ to 12″

- For pipeline, oilfield or process industry

Standard Materials

Class 150 Dimensions(Units: inch / mm) Class 300 Dimensions(Units: inch / mm) |  |