FORGED STEEL CHECK VALVES

FORGED STEEL CHECK VALVES

CONSTRUCTION & FEATURES

- Designed to API 602, ASME B16:34

- Standard Bore and Full Bore

- Piston / Lift type check valves (spring loaded as standard)

- Ball type check valves (spring loaded as standard)

- Swing type check valves

- Bolted cover & spiral wound gasket seal cover

- Welded cover or threaded and pressure seal cover

- Various types of end connections available

- Disc – soft seal discs available on request

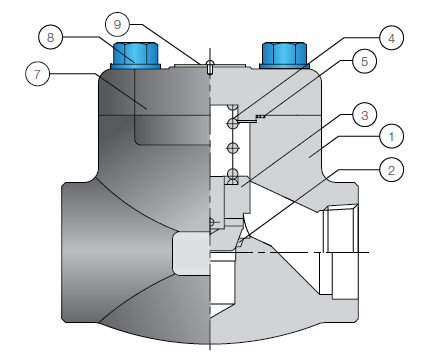

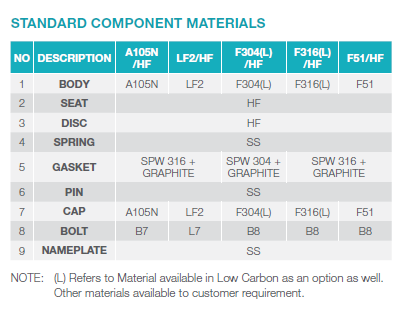

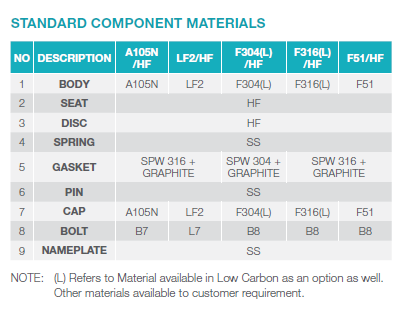

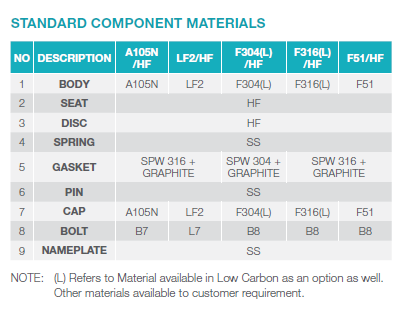

MAIN COMPONENT & PARTS

1. BODY:

Strong and Robust in ASTM forged steel material. Designed to the requirements of API 602 and ASME B16.34. Available in Standard and Full Bore design. Y pattern design available upon request.

2. SEAT:

Part of the valve trim to aPI 602, the body seat is an integral weld overlay to the valve body for Piston and Ball

type Check Valve. For Swing type Check valve, a separate seat ring is pressed and seal welded into the valve body. This eliminates potential leak paths.

3. DISC:

Part of the valve trim to API 602, the disc is in ASTM forged steel material.

4. SPRING:

Spring energized to ensure positive sealing. Option of non spring energized is also available.

5. GASKET:

Spiral Wound Type body gasket as standard.

6. PIN:

Permanent fixture of the nameplate to ensure traceability.

7. CAP:

Strong and Robust in ASTM forged steel material. Designed to the requirements of API 602 and ASME B16.34.

8. BOLT:

Alloy steel material to ASTM standards.

9. NAMEPLATE:

Allows full traceability.

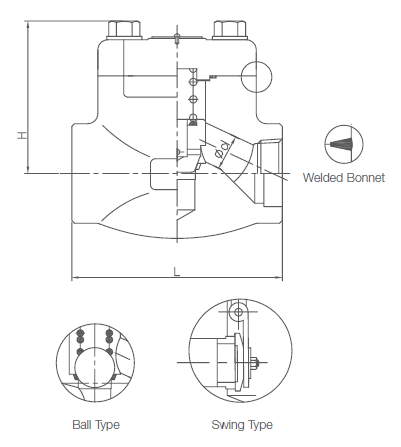

CLASS 800#

CHECK VALVES

Socket Weld & Threaded Ends Standard Bore.

SPECIFICATION

Valve Body Pressure Rating

Class 800, Max 1975 psig @ 100 F (Carbon Steel)

Temperature Rating

As per ANSI ASME B16.34

Body Construction

Bolted Cap

Welded Cap

Piston Check. Spring Loaded as standard.

Ball Type Check available

Swing Type Check available

Y Pattern available

Pup Piece welding or Extended ends available upon request.

Body Bolts

ASTM A193 Gr B7 or B8 (N/A to Welded Bonnet)

(Other Options availabe upon request)

Seats

Integral Body Seat. (Except Swing Type)

Full/Half HF (Hardfaced Stellite #6) seats or Non HF seats available

Seat / Seal Leakage

Conform to API 598.

Design Specification

API 602

ASME 16.34

Socket Weld Ends to ASME B16.11

Threaded Ends to ASME B1.20.1

End to End (L) dimensions are to manufacturer standard

NACE MR-01-75 material (when required)

Materials to ASTM standards

Special Materials are available to customer requirements

Note: Dimensions are for information only.

Order Specific arrangement drawing dimensions will be final.

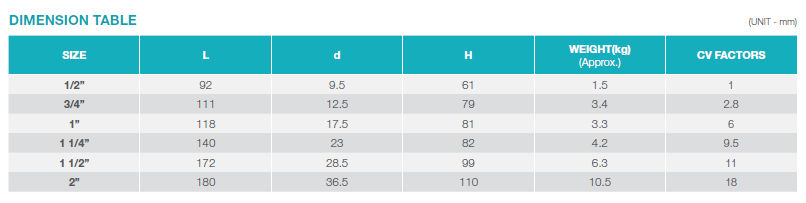

CLASS 1500#

CHECK VALVES

Socket Weld & Threaded Ends Standard Bore.

SPECIFICATION

Valve Body Pressure Rating

Class 1500, Max 3705 psig @ 100 F (Carbon Steel)

Temperature Rating

As per ASME B16.34

Body Construction

Bolted Cap

Welded Cap

Piston Check. Spring Loaded as standard.

Ball Type Check available

Swing Type Check available

Y Pattern available

Pup Piece welding or Extended ends available upon request.

Body Bolts

ASTM A193 Gr B7 or B8 (N/A to Welded Bonnet)

(Other Options availabe upon request)

Seats

Integral Body Seat. (Except Swing Type)

Full/Half HF (Hardfaced Stellite #6) seats or Non HF seats available

Seat / Seal Leakage

Conform to API 598.

Design Specification

API 602

ASME B16.34

Socket Weld Ends to ASME B16.11

Threaded Ends to ASME B1.20.1

End to End (L) dimensions are to manufacturer standard

NACE MR-01-75 material (when required)

Materials to ASTM standards

Special Materials are available to customer requirements

Note: Other Sizes and Full Bore options available upon request.

Dimensions are for information only. Order Specific arrangement drawing dimensions will be final.

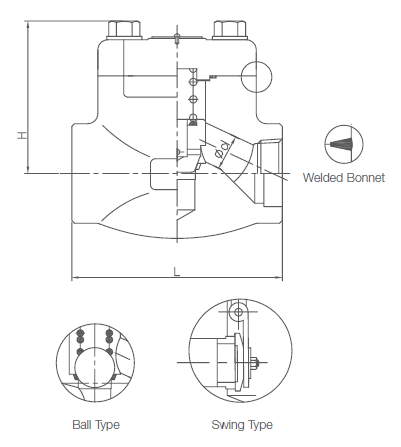

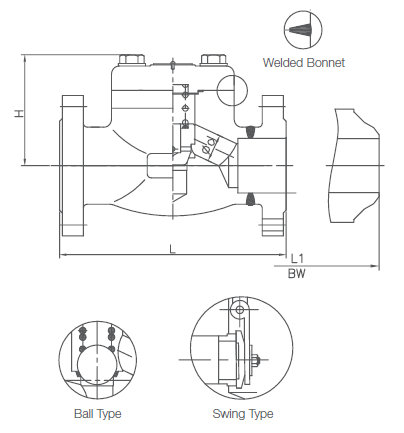

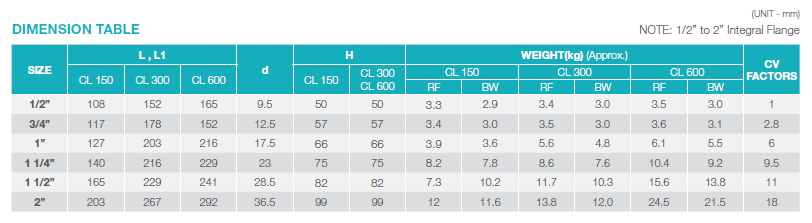

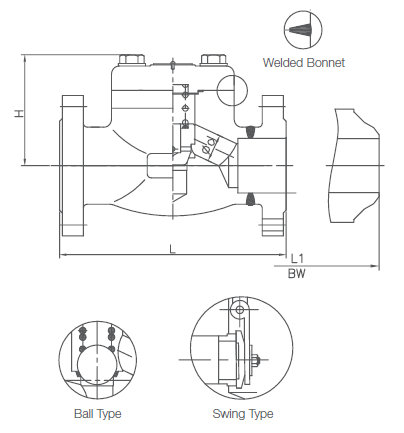

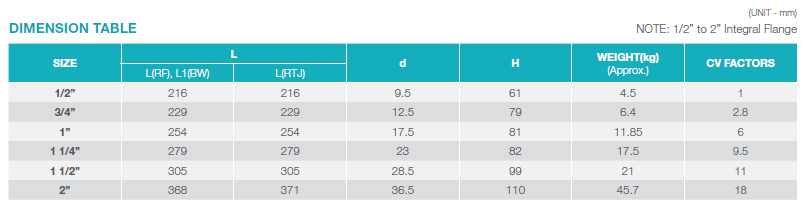

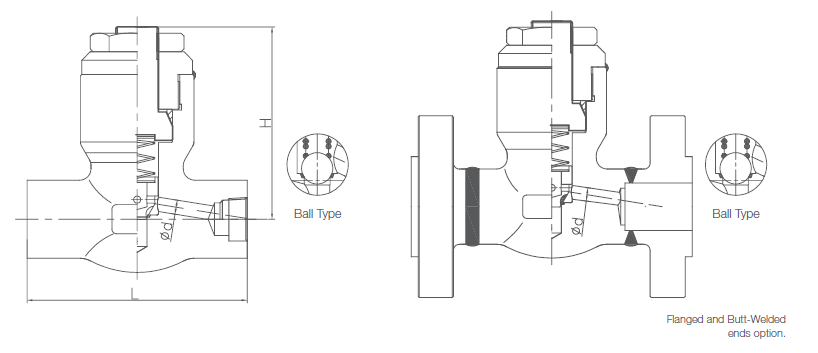

CLASS 150# - 300# - 600#

CHECK VALVES

Flange Ends Standard Bore.

SPECIFICATION

Valve Body Pressure Rating

Class 150, Max 285 psig @ 100 F (Carbon Steel)

Class 300, Max 740 psig @ 100 F (Carbon Steel)

Class 600, Max 1480 psig @ 100 F (Carbon Steel)

Temperature Rating

As per ASME B16.34

Body Construction

Bolted Cap

Welded Cap

Integral and Welded Flange available depending on size and rating.

Piston Check. Spring loaded as standard.

Ball type Check available

Swing type Check available

Y Pattern available

Body Bolts

ASTM A193 Gr B7 or B8 (N/A to Welded Bonnet)

(Other Options availabe upon request)

Seats

Integral Body Seat. (Except Swing Type)

Full/Half HF (Hardfaced Stellite #6) seats or Non HF seats available

Seat / Seal Leakage

Conform to API 598.

Design Specification

API 602

ASME B16.34

Flange ends to ASME B16.5

Butt Weld ends to ASME B16.25

Face to Face to ASME B16.10

NACE MR-01-75 material (when required)

Materials to ASTM standards

Special Materials are available to customer requirements

Note: Other Sizes and Full Bore options available upon request.

Dimensions are for information only. Order Specific arrangement drawing dimensions will be final.

CLASS 1500#

CHECK VALVES

Flange Ends Standard Bore.

SPECIFICATION

Valve Body Pressure Rating

Class 1500, Max 3705 psig @ 100 F (Carbon Steel)

Temperature Rating

As per ASME B16.34

Body Construction

Bolted Cap

Welded Cap

Integral and Welded Flange available depending on size and rating.

Piston Check. Spring loaded as standard.

Ball type Check available

Swing type Check available

Y Pattern available

Body Bolts

ASTM A193 Gr B7 or B8 (N/A to Welded Bonnet)

(Other Options availabe upon request)

Seats

Integral Body Seat. (Except Swing Type)

Full/Half HF (Hardfaced Stellite #6) seats or Non HF seats available

Seat / Seal Leakage

Conform to API 598.

Design Specification

API 602

ASME B16.34

Flange Ends to ASME B16.5

Butt Weld Ends to ASME B16.25

Face to Face to ASME B16.10

NACE MR-01-75 material (when required)

Materials to ASTM standards

Special Materials are available to customer requirements

Note: Other Sizes and Full Bore options available upon request.

Dimensions are for information only. Order Specific arrangement drawing dimensions will be final.

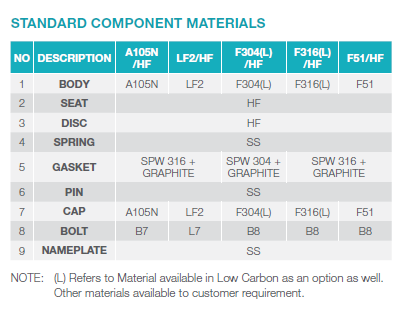

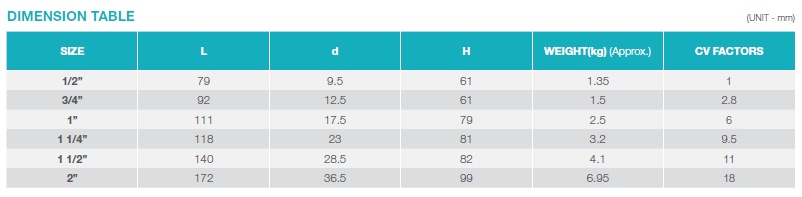

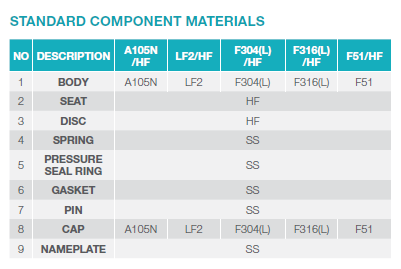

CLASS 2500#

HIGH PRESSURE CHECK VALVE

Pressure Seal Cover, Socket Weld & Threaded Ends

Note: (L) Refers to Material available in Low Carbon as an option as well.

Other materials available to customer requirement.

Note: Other Sizes and Full Bore options available upon request.

Dimensions are for information only. Order Specific arrangement drawing dimensions will be final.

SPECIFICATION

Valve Body Pressure Rating

Class 2500, Max 6170 psig @ 100 F (Carbon Steel)

Temperature Rating

As per ASME B16.34

Body Construction

Pressure Seal Cap (Welded Cap option)

Piston Check. Spring Loaded as standard.

Ball Type Check available

Pup Piece welding or Extended ends available upon request.

Welded Flange Option available upon request.

Seats

Integral Body Seat. (Except Swing Type)

Full/Half HF (Hardfaced Stellite #6) seats or Non HF seats available

Seat / Seal Leakage

Conform to API 598.

Design Specification

ASME B16.34

NACE MR-01-75 material (where required)

Materials to ASTM standards

Special Materials are available to customer requirements

Socket Weld Ends to ASME B16.11

Threaded Ends to ASME B1.20.1

End to End (L) dimensions are to manufacturer standard

Other Ends Option

Flange Ends to ASME B16.5

Butt Weld Ends to ASME B16.25

Face to Face to ASME B16.10