Trunnion Mounted Ball Valves

TRUNNION MOUNTED BALL VALVES

TECHNICAL FEATURES

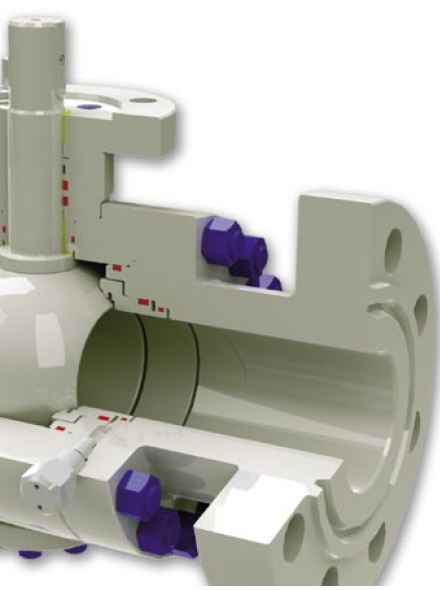

TRUNNION MOUNTED DESIGN

DESIGN

KVC Trunnion Mounted bolted construction Ball Valves are designed and manufactured in accordance with the latest industry standards. Our split body design gives ease of maintenance on site.

Trunnion Mounted Valves are available in both soft seated and metal seated design.

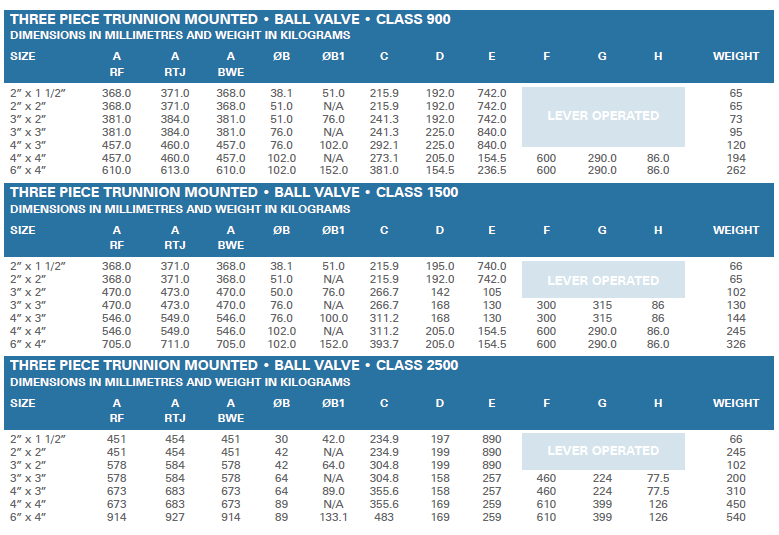

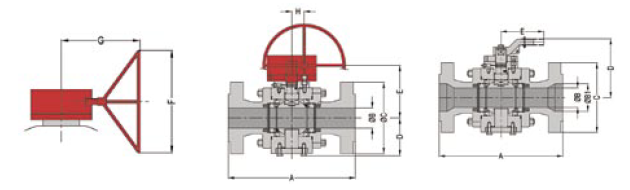

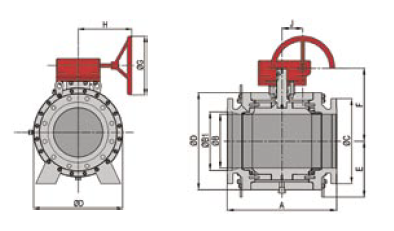

Special face to face dimensions can be supplied. All valves are available in Full or Reduced Bore, with Raised Face, Ring Type Joint, Hub End, Butt Weld or Socket end connections. Pressure rating range from ANSI 150 thru ANSI 2500, compact flanges and higher pressure ratings are available on request.

Valves are supplied as Lever Operated, Gear Operated or Actuated to customer’s specification.

MATERIAL SELECTION

Valves are manufactured in a range of materials such as Carbon Steel, Low Temp Carbon Steel, Stainless Steel, Duplex, Super Duplex, Monel, Inconel and other Special Alloys.

BODY/CAP

Trunnion Mounted valves are normally manufactured from forged rings, which ensures a high integrity material grain structure and

improved sealing between the components. Sealing is by O-rings and Graphite rings. The Graphite ring continues to provide a seal

in the event of a fire. O-rings can be supplied suitable for AED applications in a variety of materials.

SEAT

Independent seats with preloaded springs are always in contact with the Ball giving a perfect seal even at low pressure. The replaceable seat rings and soft inserts can be supplied in materials to suit most service conditions.

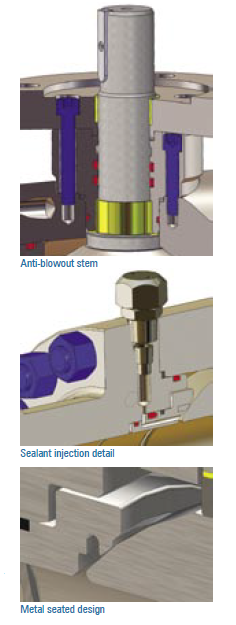

For very high temperatures, sealing is ensured by metal to metal seats whereby the Ball and Seats are coated with Tungsten Carbide and lapped together. Most sizes and classes have Sealant Injection system fitted as standard. This allows emergency sealing to be carried out in the event of damage to the soft seat.

STEM

Stems are manufactured separately from the Ball and feature an anti blow-out design. Stems are supported by RPTFE lined bushes, which reduce valve torque. Stem sealing is by O rings and graphite rings. From 2” and above stems are supplied with sealant injection system.

BALL

Balls are supplied in Forged or Cast Stainless Steel, Duplex or Carbon Steel with ENP. The Trunnion Mounted design reduces operating torque and seat wear.

ANTI STATIC DEVICE

Electrical conductivity is achieved by fitting a positive contact device between the Stem, Ball and Bonnet.

DOUBLE BLOCK AND BLEED

Valves are equipped with a vent plug, which allows the cavity to be relieved when pressure is applied to both sides of the Ball simultaneously.

TESTS

Valves are tested in accordance with BS EN 12266 Pt 1&2, API 6D, API 598 and ASME B16.34

FIRE TEST CERTIFICATION

Valves are designed and certified by an Independent Authority according to API 607 and API 6FA.

EXTERNAL COATING

Carbon Steel valves are normally supplied with KVC standard paint finish. Valves can also be unpainted or finished to customers paint specification.

ACCESSORIES

Include locking devices, pipe pups, extended bonnets and actuators. Suitable materials, components, seats and O rings can be supplied for Valves with Explosive Decompression or Cryogenic applications.

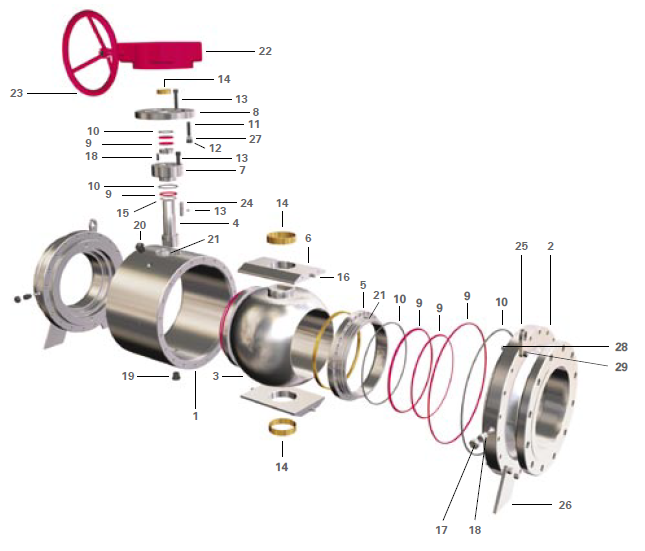

TRUNNION MOUNTED BALL VALVES

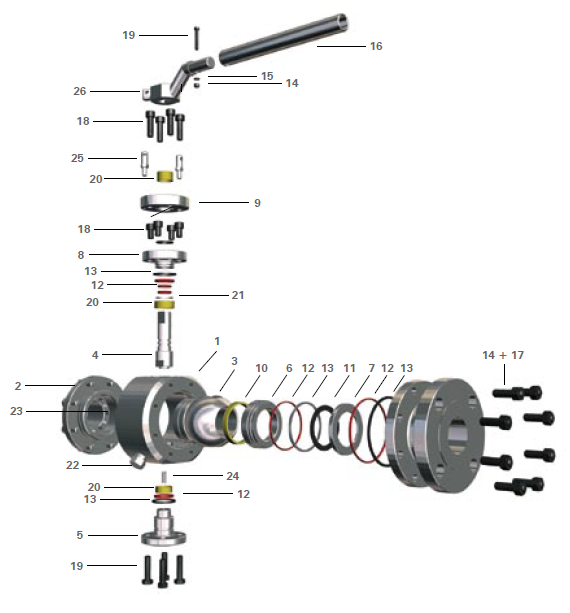

SOFT SEATED DESIGN, 2” TO 6” RB LEVER OPERATED

No. Description

- body

- Cap

- Ball

- Stem

- Trunnion Flange

- Seat Retainer

- Seat Follower

- Bonnet

- Bonnet Flange

- Seat Insert

- Seat Spacer

- ‘O’ Ring

- Firesafe Seal

- Nut

- Washer

- Lever Tube

- Stud

- Socket Head Screw

- Hex Head Screw

- Du Bush

- Thrust Washer

- Drain Plug

- Spring

- Anti Static Spring

- Stop Pin

- Lever Head

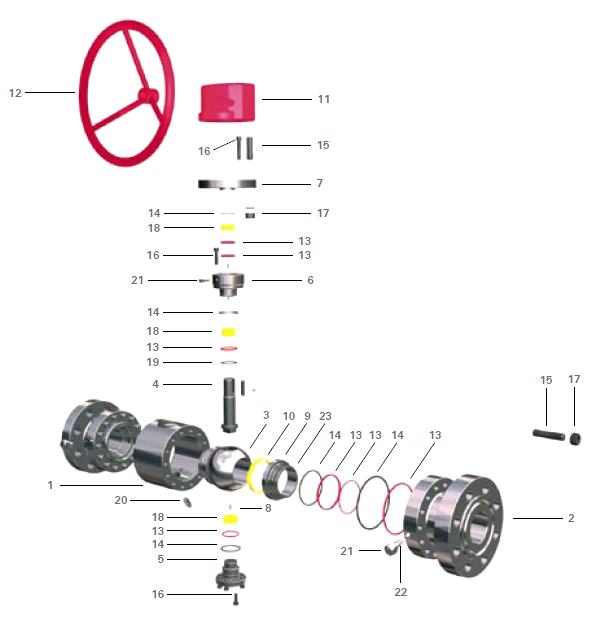

SOFT SEATED DESIGN, 3” FB TO 6” RB GEAR OPERATED

No. Description

- body

- Cap

- Ball

- Stem

- Trunnion Flange

- Bonnet

- Bonnet Flange

- Anti Static Device

- Seat Retainer

- Seat Insert

- Gearbox

- Hand Wheel

- ‘O’ Ring Seal

- Firesafe Seal

- Studs

- Cap Screws

- Nuts

- Bearing Brush

- Thrust Bearing

- Bleed Plug

- Sealant Fitting

- Check Valve

- Springs

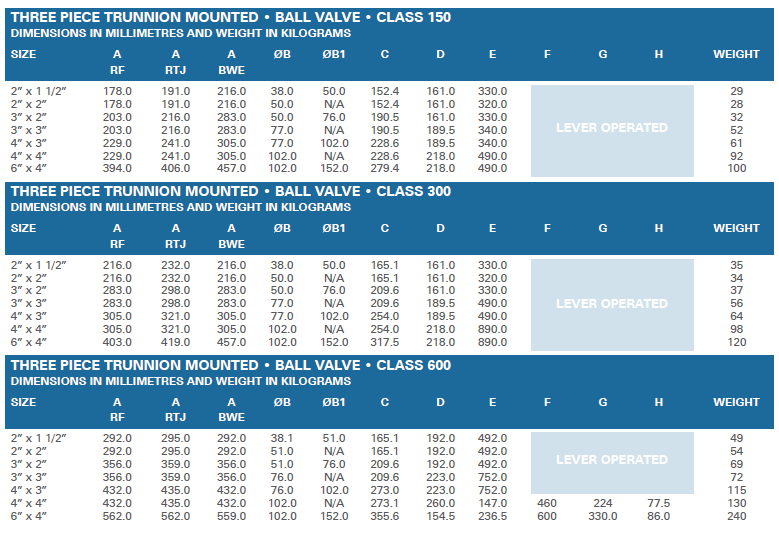

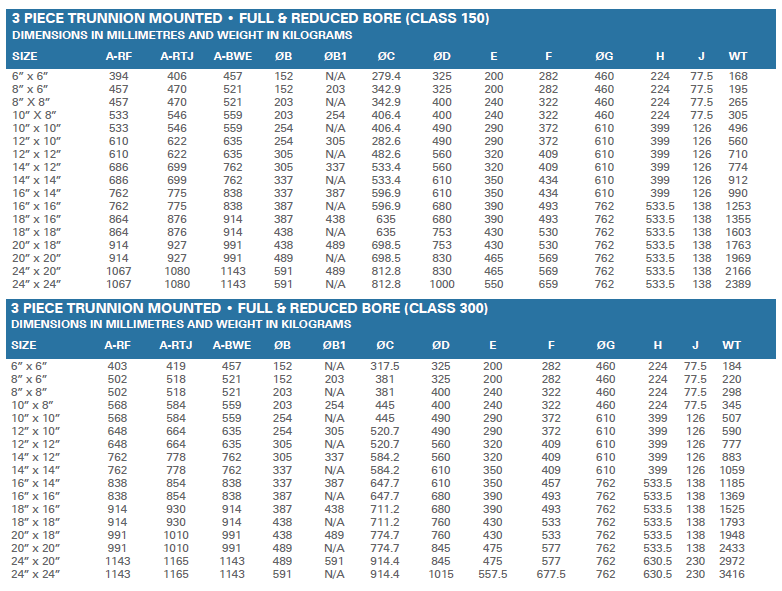

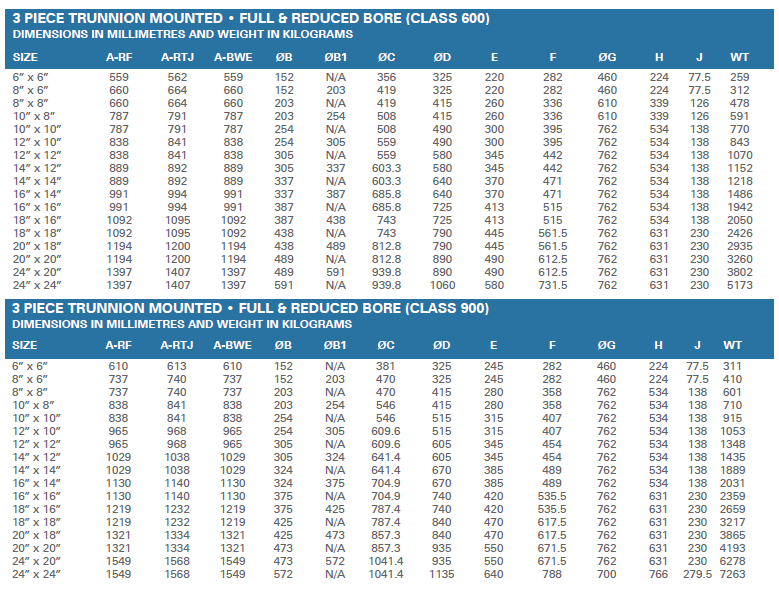

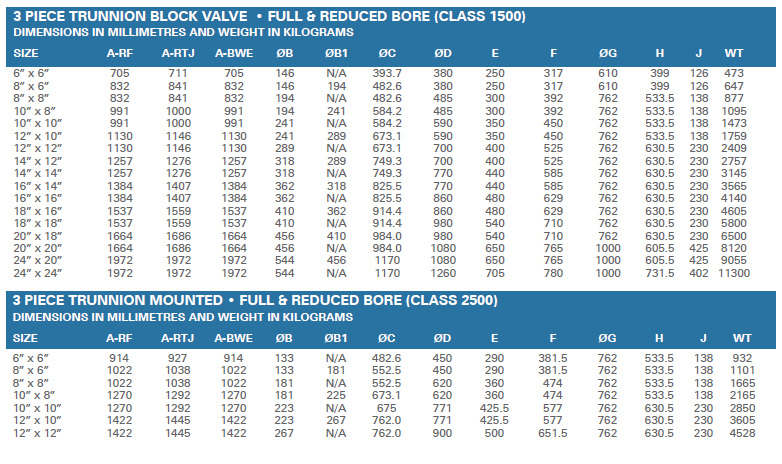

GENERAL NOTES FOR DIMENSIONAL TABLES

- All sizes given in millimetres and are approximate.

- All weights given in kgs and are approximate.

- Weights given for flanged valves include gearbox unless otherwise stated.

- Dimensions shown may be revised at any time. Use certified dimensional drawings for critical areas.

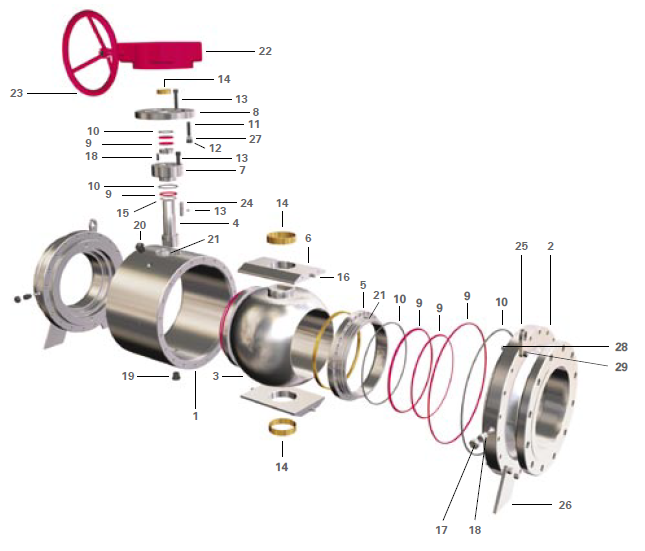

SOFT SEATED DESIGN, 6” FB UPWARDS

No. Description

- body

- Cap

- Ball

- Stem

- Seat Retainer

- Bearing Plate

- Bonnet

- Bonnet Flange

- ‘O’ Ring

- Firesafe Seal

- Stud

- Nut

- Cap Screw

- Du Bush

- Thrust Washer

- Dowel Pin

- Sealant Fitting

- Check Valve

- Drain Plug

- Vent Plug

- Spring

- Gearbox

- Handwheel

- Key

- Lifting Lug

- Support Feet

- Spring Washer

- Bolt

- Nut

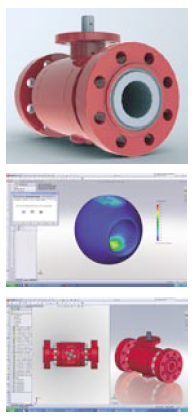

METAL SEATED DESIGN

No. Description

- body

- Cap

- Ball

- Stem

- Seat Retainer

- Bearing Plate

- Bonnet

- Bonnet Flange

- ‘O’ Ring

- Firesafe Seal

- Stud

- Nut

- Cap Screw

- Du Bush

- Thrust Washer

- Dowel Pin

- Sealant Fitting

- Check Valve

- Drain Plug

- Vent Plug

- Spring

- Gearbox

- Handwheel

- Key

- Lifting Lug

- Support Feet

- Spring Washer

- Bolt

- Nut

KVC (UK) Ltd design, manufacture and supply a range of metal seated ball valves from 1” up to 48”, CL150 - CL2500 and API 5000 & 10000.

(All dimensions and approx weights are as the Trunnion mounted tables.)

Metal seated valves are manufactured in various sealing arrangements from o-rings or enerseals or full grafoil construction to suit the required environment and operating conditions, including high temperature and abraisive service.

The ball and seat sealing faces are coated with a hard surface material and individually paired and lapped together for efficient sealing.

Hard Coatings available are:

- Stellite

- Chrome Carbide

- Tungsten Carbide

- Plasma

Latest computer aided design technology used throughout all stages of product realisation.

These are selected either by customer specification or KVC (UK) Ltd engineering department recommendation for advised application.