KVC UK Ltd

KVC UK Ltd

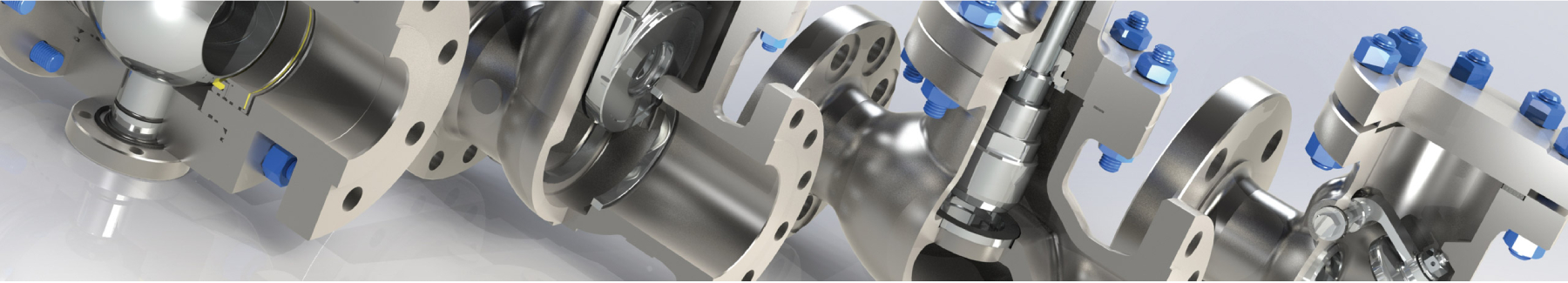

KVC UK Ltd specializes in the Design and Manufacture of Pipeline Valves for the Oil, Gas, Chemical, Petrochemical, Pipeline and Water Industries worldwide. Our valves are used in offshore, onshore and sub-sea applications. All valves are manufactured to the highest quality standards and are fully tested before leaving the factory.

Applicable Standards

KVC UK Ltd design and manufacture valves in accordance with latest standards such as: API, ASTM, ASME, ISO, B.S. MSS and NACE standards. The valves may be designed, manufactured and tested in accordance with other international standards on request, or to meet specific customer requirements.

Soft Seated Trunnion Mounted Valves

KVC UK Ltd Soft Seated Trunnion Mounted Ball Valves are designed and manufactured in accordance with the latest industry standards. Valve range from 2" - 48" Class 150 - 2500.

Full or Reduced Bore, with Raised Face, Ring Type Joint, Hub End, Butt Weld or Socket end connections. Compact Flange to Norsok standards also available. Combination of end connection types can also be designed and manufactured to the customers' requirements.

Valves are supplied as Lever Operated, Gear Operated or Actuated to customer's specification. Valves are manufactured mostly from Forged, which ensure a high integrity material grain structure and improved sealing between the components.

Standard Sealing by O-rings and Graphite rings. The Graphite ring continues to provide a seal in the event of fire. O-rings can be supplied suitable for RGD (Rapid Gas Decompression) applications in a variety of materials. Energised Lip seal designs are also available to cope with more extreme service conditions and temperatures.

The core design has many standard key features including:

- Forged Material Construction, ensuring high integrity grain structures.

- Independent preloaded seats giving a positive seal even at low pressure.

- Anti-Blowout Stem.

- Anti-Static Design and tested.

Fire safe and tested Design toAPI 607 5th Edition.

Floating Ball Valves

Floating Ball valves are manufactured in three main types;

- One Piece Body Construction.

- Two Piece Body Bolted Construction.

- Three Piece Body Bolted Construction.

Valves can be supplied Full or Reduced Bore and are manufactured in either cast or forged material. Bolted and Screwed Body connections give ease of service and maintenance on site. Valves can be supplied with either Raised Face, Ring Type Joint, Socket Weld or Screwed End connections. Pressure rating is from ANSI CL150 thru ANSI CL2500. Higher pressures can be supplied on request. Valves are supplied with Lever or Gear Operator.

Metal Seated Trunnion Mounted Ball Valves

KVC UK Ltd Metal Seated Ball Valves are designed and manufactured from 2" up to 24", CL150 – CL1500. Our Metal Seated Ball Valves are manufactured to the highest standards and quality to ensure a precision engineered product is supplied to our customer.

Metal seated valves are available in various sealing arrangements and construction to suit the required environment and operating conditions, including high temperature and abrasive services. The ball and seat sealing faces are coated with a hard surface material and individually paired and lapped together for efficient sealing.

Hard coatings available are:

- Stellite.

- Chrome Carbide.

- Tungsten Carbide.

- Plasma.

Gate, Globe and Check Valves

KVC UK Ltd range of Gate, Globe and Check valves includes Cast steel to API and BS standard and Forged steel to API 602 standards. We are able to supply a wide variety of such products with good integrity standards proven from years of experience and supply. For more information of these products, please check with our agents and distributors.

SEALING TECHNOLOGY

SEAT MATERIALS

FILLED PTFE

Mixed with an insert filler at the processing stage to give a stiffer material than virgin polymer, this Material gives good chemical resistance and low coefficient of friction.

PCTFE

Capable of higher loads than PTFE. Good low temperature strength, excellent chemical resistance.

DEVLON V (MONOCAST NYLON)

For services higher than filled PTFE, Devlon V gives good resistance to oils, greases and solvents. Its low water absorption gives superior dimensional stability.

PEEK

This material is an abrasion resistant high performance thermo plastic which retains good tensile and flexural properties at temperatures in excess of plus 250 degrees C.

METAL SEATED

Tungsten or plasma coating provides sealing for extremely high temperatures and abrasive services. The ball and seat retainer sealing face are lapped and paired together before and after coating to ensure a high integrity seal.

O-RINGS AND GASKETS

SEAL MATERIALS

VITON® (FKM)

Shore hardness 90. Excellent resistance to petroleum products and solvents.

NITRILE (NBR)

Shore hardness 90. Good general purpose material.

FLUOROSILICONE

Suitable for low temperature applications.

VITON® AED (FKM/ RGD)

Shore hardness 90. Grades such as FR58-90* and Endura V91J*.

HNBR AED

Shore hardness 90. Grades such as Endura Z95X* and Elastolion 985/101®*.

FFKM

Superior chemical resistance and high temperature performance to most other o-ring grades. Grades such as Kalrez® and Perlast.

ENERGISED LIP SEALS.

Used in more extreme temperature or pressure conditions. Available in a wide range of springs from 316 to Inconel and seal material varying from PTFE to PEEK depending on application.

* O-rings specified as explosive decompression resistant tested, will be in accordance with Norsok M-710 testing specification.

FIRESAFE MATERIAL

Natural Graphite is purified, expanded, and pressed into a typical hexagonal crystalline structure of Graphite which remains permanently flexible. Supplied in moulded ring form it is suitable for temperatures of minus 250 deg C to plus 2500 deg C in non-oxidising atmosphere and up to plus 500 deg C in oxygen. Its features include natural resilience, self lubricating, almost chemically inert, no fillers or binders and no structural change against pressure, temperature or time. Metal Seated valves suitable for high temperature and abrasive service have a full grafoil sealing arrangement.